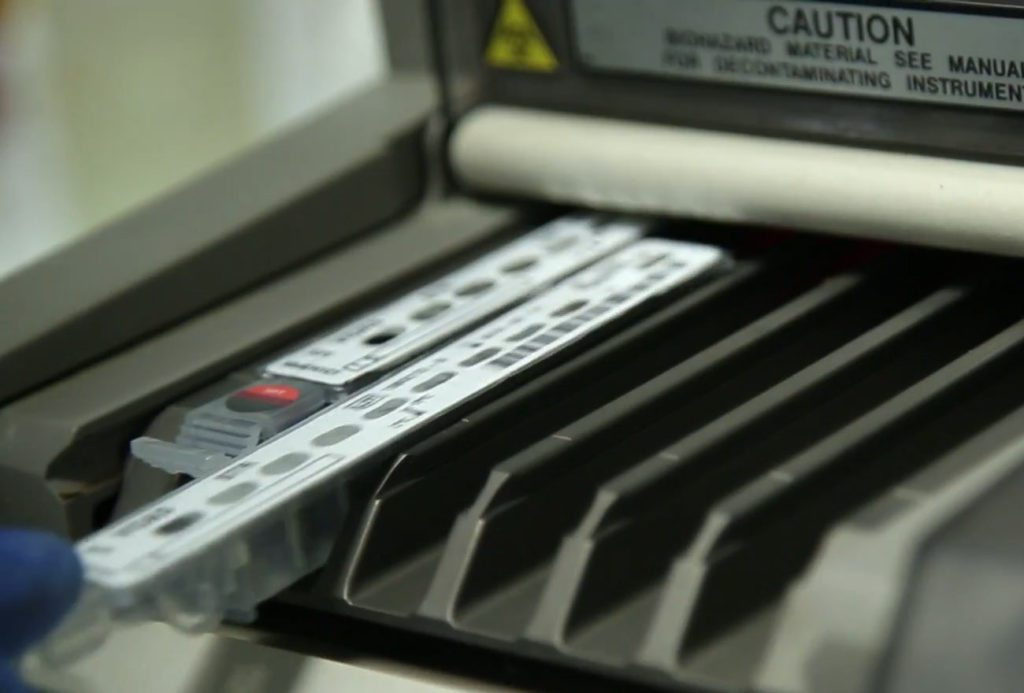

Optimization begins with a thorough and rigorous analysis of the production process.

Our approach is based on identifying inefficiencies, bottlenecks and opportunities for improvement through a detailed technical evaluation of each stage of the system.

Once the critical point is identified, we design automation solutions that optimize overall performance, either through software, such as SCADA systems or PLC programming; or specialized industrial hardware, such as sensors, actuators, weighing systems or industrial control devices.

✔️ Integral approach: analysis - engineering - technology

We combine technical know-how and the most innovative tools to create meaningful, feasible and result-oriented automated solutions.

✔️ Results-oriented automation

We propose solutions that improve operational efficiency, reduce costs, increase system reliability and facilitate real-time decision making.

✔️ Technology adapted to every need

From PLC programming to sensorization of production lines: we apply the right solution, without cost overruns or underutilization.

How do we optimize industrial processes?

Integrating supervisory and control systems (SCADA, HMI)

Automating repetitive tasks with PLCs and dedicated devices

Digitizing industrial data collection and analysis

Facilitating predictive maintenance and full traceability

Improving decision making with real time data

Benefits of optimizing your processes with Inaptek

Improved overall system efficiency

Reduction of operating costs

Increased process reliability and availability

Data-driven decision making

Scalability and technical sustainability

Our commitment: to accompany each client in their technological transformation, providing experience, innovation and continuous support to guarantee tangible and lasting results.

Frequently asked questions on process optimization

How do I know if my process can be optimized?

If you detect downtime, repetitive errors or bottlenecks, there is probably room for improvement. We help you to analyze it without obligation.

Does automating a process mean replacing personnel?

Not necessarily. In many cases, the team is freed from repetitive tasks to focus on higher-value work.

Can you integrate automation with my existing systems?

Yes, we adapt our solutions to your existing systems to ensure compatibility and operational continuity.

How is the return on process optimization measured?

We calculate the estimated ROI before the project and measure it after implementation, evaluating savings, time and performance.